innovation of quality control

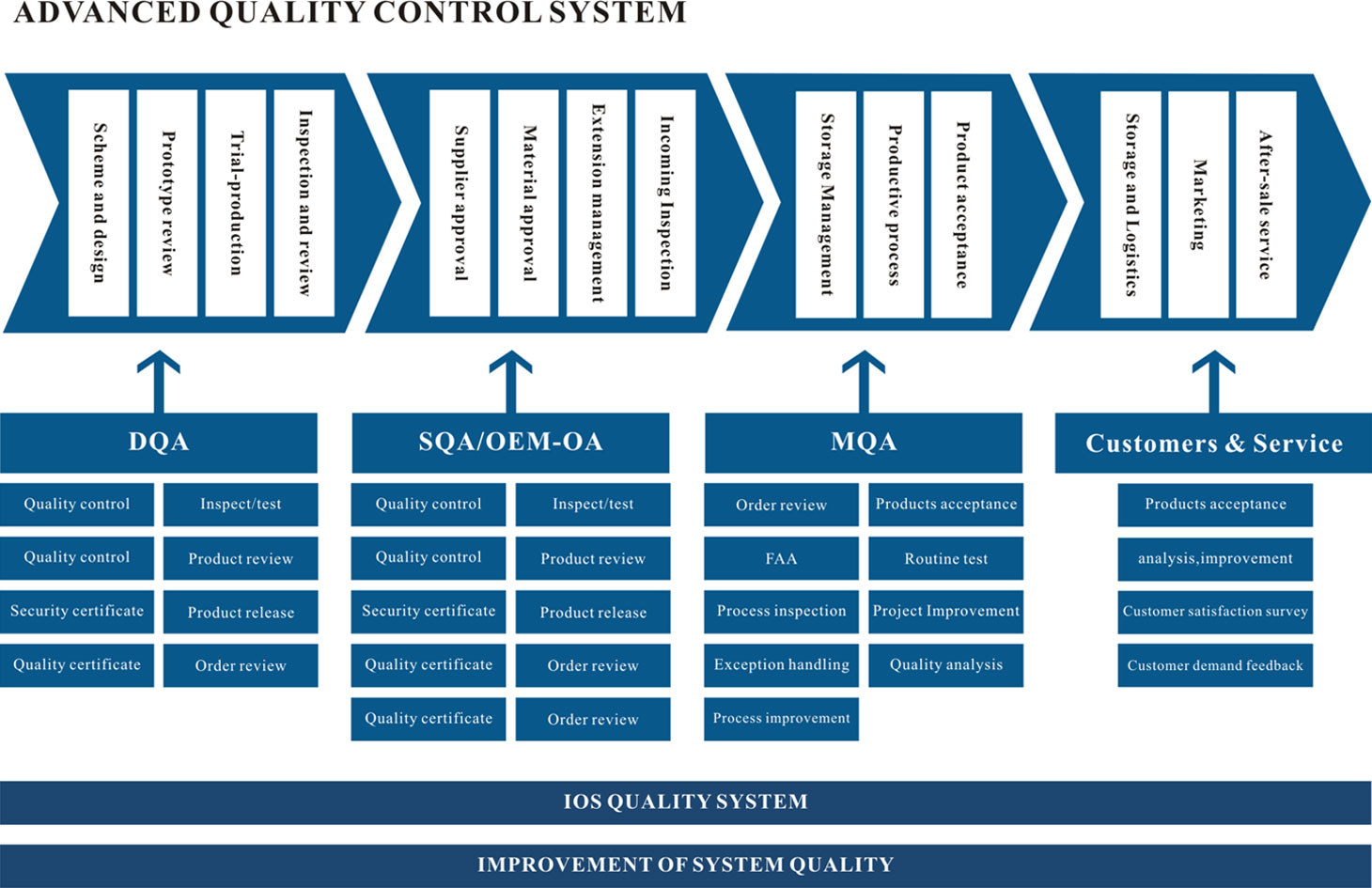

ELECMAN has a comprehensive quality control process in place to ensure that their electrical products are of the highest quality and meet customer requirements. Here are some of the ways in which ELECMAN controls the quality of their electrical products:

Design and Development: ELECMAN designs their products with input from customers, engineering teams, and quality control teams to ensure that the product meets the highest quality standards. They use design tools such as simulations and prototypes to evaluate and optimize the product design before manufacturing.

Manufacturing: ELECMAN has advanced manufacturing facilities which utilize advanced technologies and processes to produce products that meet the highest quality standards. ELECMAN uses reliable and efficient manufacturing techniques and performs regular inspections of the manufacturing process to reduce the likelihood of defects and non-conformances.

Testing and Validation: ELECMAN conducts rigorous testing on all their products at every stage of the manufacturing process to ensure that the product meets customer requirements and industry standards. ELECMAN uses advanced testing tools such as vibration testing, thermal testing, and endurance testing to ensure quality durability and reliability.

Quality Control: ELECMAN has a strict quality control system that spans all stages of the product development and manufacturing process. ELECMAN also regularly monitors customer feedback and has a dedicated quality control team to identify, analyze and address any quality issues that may arise.

Overall, ELECMAN’s rigorous quality control process ensures that their electrical products are of the highest quality, meet customer requirements, and perform reliably over the lifetime of the product.